- Home

-

![]()

You are here: Home » Blogs » Oral Care Guidebook » Miswak Toothpaste Tablets: Technical Trends & OEM Development Insights for 2025

You are here: Home » Blogs » Oral Care Guidebook » Miswak Toothpaste Tablets: Technical Trends & OEM Development Insights for 2025Miswak Toothpaste Tablets: Technical Trends & OEM Development Insights for 2025

Views: 0 Author: Site Editor Publish Time: 2025-11-27 Origin: Site

Intro: 2025 Is the Industrial Turning Point for Miswak in Waterless Oral Care

By 2025, the competition in waterless toothpaste tablets has shifted from “eco-friendly concept” to true industrial scalability. Brands are no longer satisfied with generic mint tablets—they are actively looking for ingredients that represent cultural value, natural care, and scientific credibility.

This is exactly why Miswak (Salvadora persica) is rising again as a global formulation focus.However, making a stable Miswak toothpaste tablet is far beyond simply adding Miswak powder to a base formula. The powder behavior, tablet structure, disintegration system, flavor engineering, active stability, and batch consistency determine whether a product is ready for mass production and long-term commercialization.

Based on over a decade of experience in OEM/ODM waterless oral-care manufacturing, this article outlines the real technical challenges and industrial trends of Miswak toothpaste tablets in 2025.

1. What the Market Cannot See: The Real Engineering Challenges of Miswak in Solid Formulation

Most public articles talk about the cultural and natural benefits of Miswak.But engineers know the real difficulty lies in how Miswak behaves as a powder inside a compressed solid dosage form.

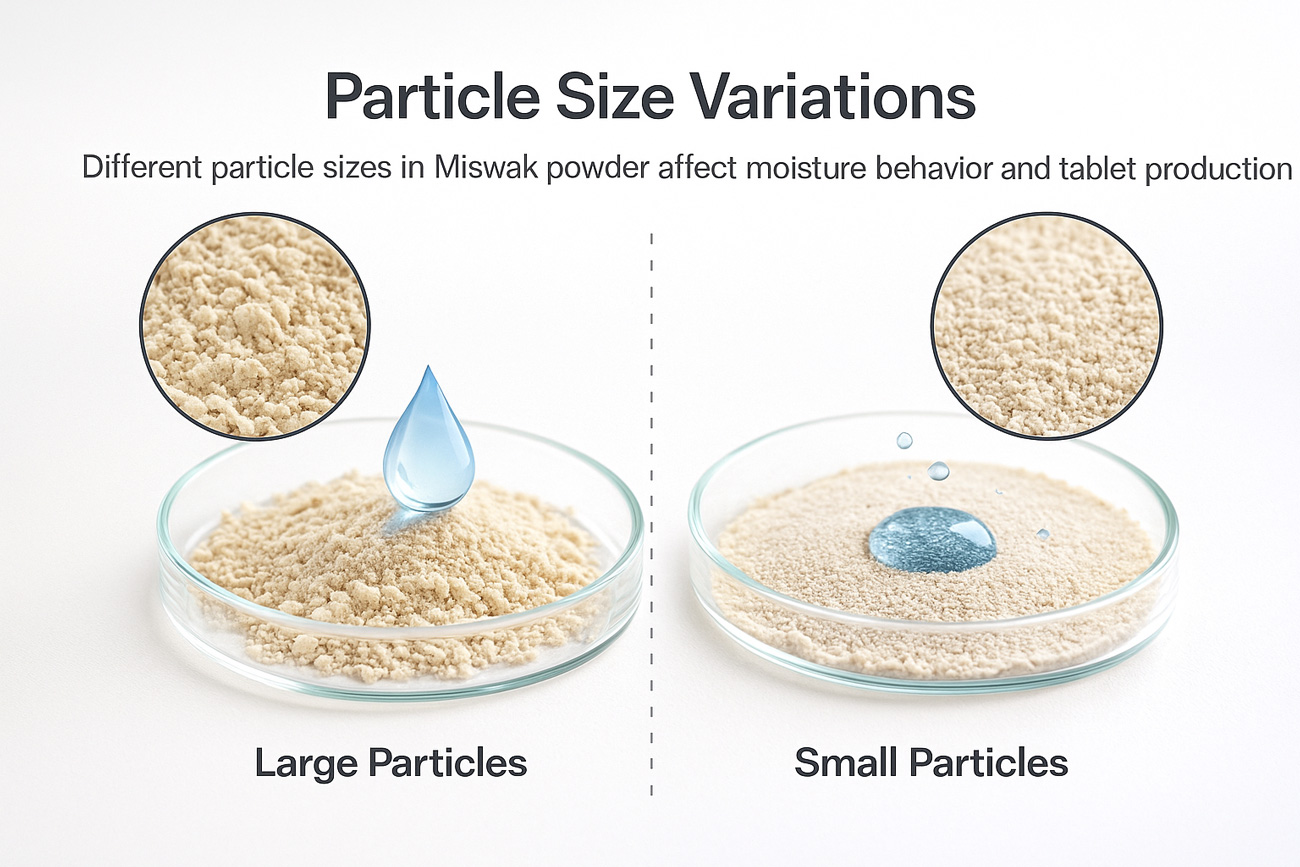

1.1 Irregular Particle Size Directly Affects Tablet Structure

Common Miswak powder issues:

High fiber content

Wide particle size distribution

Batch-to-batch moisture variation

Noticeable color differences

Possible issues in tablets:

Coarse particles → unstable disintegration

Over-fine particles → fragile tablets and poor hardness

High moisture → weak compaction and higher water activity

Color variation → inconsistent appearance between batches

Therefore, the first step in Miswak formulation is not the percentage—it is:

✔ Powder classification

✔ Standardizing particle size

✔ Moisture & water-activity controlThis step alone separates experienced factories from inexperienced ones.

1.2 High Friction and Poor Flowability: The Hidden Problem of Natural Powders

Miswak’s natural fibers cause a significantly higher friction coefficient, leading to:

Uneven feeding → fluctuating tablet weight

Faster tooling wear

Uneven pressure distribution → internal voids or cracks

The engineering solutions include:

Optimizing lubricant systems

Adjusting excipient ratios

Using low-friction tooling

Applying flow-enhancing functional excipients developed specifically for solid oral-care

These are practical, machine-level optimizations—not theoretical assumptions.

1.3 Miswak Interferes With Disintegration — Engineering Compensation Is Required

Plant fibers naturally slow disintegration.

This means the upper limit of Miswak addition is determined not by marketing, but by:Disintegrant gradient testing

Particle-size combinations

Tablet density management

Pressure curve adjustments

A professionally tuned formula should achieve 15–25 seconds of consistent disintegration, even at scale.

![Miswak Particle Size Variations Miswak Particle Size Variations]()

2. Active Stability: The Most Overlooked but Most Critical Topic for 2025

Unlike synthetic actives, Miswak contains heat-sensitive and oxidation-sensitive components. Stability is influenced by temperature, oxygen, water activity, light exposure, and processing time.

2.1 Water Activity (Aw) Control

If the raw material's Aw is too high, issues may include:

Faster degradation of natural actives

Risk of moisture absorption in finished tablets

Dull or muted flavor

Increased microbiological risk

A mature OEM will perform:

Incoming water-activity testing

Drying or conditioning when needed

Secondary testing before mixing

2.2 Protecting Miswak’s Actives During Processing

High-speed mixing can cause temperature rise, which accelerates degradation.

Engineering controls include:Low-temperature mixing

Stepwise mixing programs

Paddle types that reduce shear stress on plant powders

These procedures are specific to solid oral-care—not borrowed from toothpaste manufacturing.

2.3 Preventing Oxidation & Color Shift

Miswak contains polyphenols, which oxidize easily.

To maintain color and activity:Add natural antioxidant systems

Reduce oxygen exposure during packaging

Conduct light-stability evaluations

Implement a measurable color-difference management system

This is key for ensuring both appearance and functional stability in shelf-life tests.

3. Industrial-Scale Manufacturing: Consistency Is the Real Barrier

The hardest part of Miswak toothpaste tablets is not making a prototype—it is producing 10,000–100,000 bottles consistently.

3.1 Color Variation: The Constant Challenge of Natural Powders

Plant-based ingredients vary with:

Harvest season

Climate

Extraction conditions

Professional factories adopt:

Colorimeter standards

Color-grading cards

Defined acceptable deviation thresholds

Uniform mixing procedures

Color-compensation strategies when required

This avoids visible shade differences across batches.

3.2 Tablet Weight Stability Determines User Experience

Weight variation affects:

Disintegration

Mouthfeel and cleaning performance

Active-ingredient delivery

A robust system includes:

Stable feeding equipment

Bulk-density management

Pressure compensation adjustments

Automatic weight monitoring

Industry expectation: ±2% tablet weight variation.

3.3 Packaging Has a Direct Impact on Product Stability

Common packaging types:

Glass jars (best stability)

Aluminum tins

Paper pouches (require strict moisture & oxygen protections)

Each packaging requires full stability validation:

Moisture-ingress testing

Light-exposure testing

Seal-integrity checks

Transportation vibration assessments

This step is often ignored by small manufacturers but essential for export-ready products.

4. Flavor Engineering: The Decisive Factor for Consumer Acceptance

Miswak has a natural herbal, slightly astringent note. If not properly balanced, consumers may reject the product on first use.

4.1 Balancing Herbal Notes With Modern Freshness

Critical considerations:

Too strong cooling agents → overwhelm Miswak’s identity

Too strong herbal notes → increase bitterness/astringency

A professional flavor system requires:

Blending different mint oils

Adjusting sweetness gradients

Controlling cooling-agent release curves

The goal: clean, refreshing, yet naturally herbal.

4.2 Flavor Must Be Compatible With Tablet Compression

Solid-form flavors differ from toothpaste or mouthwash flavors. They must:

Resist pressure

Avoid absorbing moisture

Maintain integrity during mixing

Provide stable, gradual release

This is a key threshold for true waterless oral-care formulation capability.

5. OEM Trends for Miswak Toothpaste Tablets in 2025

Based on recent development requests and market launches, three clear trends are emerging.

Trend 1 — Miswak Is Moving From “Supporting Ingredient” to “Core Concept”

Brands now request:

Miswak-centered packaging

Stronger communication around natural herbal cleansing

Full Miswak product lines

It is becoming a mainstream product direction rather than a niche concept.

Trend 2 — Combination Formulas Are Increasing Rapidly

Popular combinations include:

Miswak + Hydroxyapatite

Miswak + Xylitol

Miswak + Papain plant enzyme

The goal is to combine natural identity with modern functionality.

Trend 3 — Flavor Innovation Is Becoming a Differentiation Power

Consumers want:

Gentle herbal freshness

Softer botanical notes

Non-irritating but clean mouthfeel

Brands will compete heavily on flavor innovation.

Conclusion: The Future of Miswak Toothpaste Tablets Belongs to Factories With Real Technical Strength

Miswak is a natural ingredient with complex powder behavior and stability challenges.

To achieve reliable mass production, factories must excel in:Powder-engineering capability

Disintegration-system optimization

Botanical-raw-material handling

Tablet-compression engineering

Flavor-system design

Batch-consistency and stability control

As waterless oral care enters its next stage, brands increasingly need manufacturing partners that can make Miswak products stable, consistent, and scalable—not just functional in prototypes.

Factories with these capabilities will become the true strategic partners in the global expansion of natural solid oral-care products.

Related ProductsProduct Category

Other Links